TECHNICAL CHARACTERISTICS

- Microprocessor operation

- Iron-constant thermocouple (J) protected input

- Adjustment range 0-900°.

- Cold junction compensation

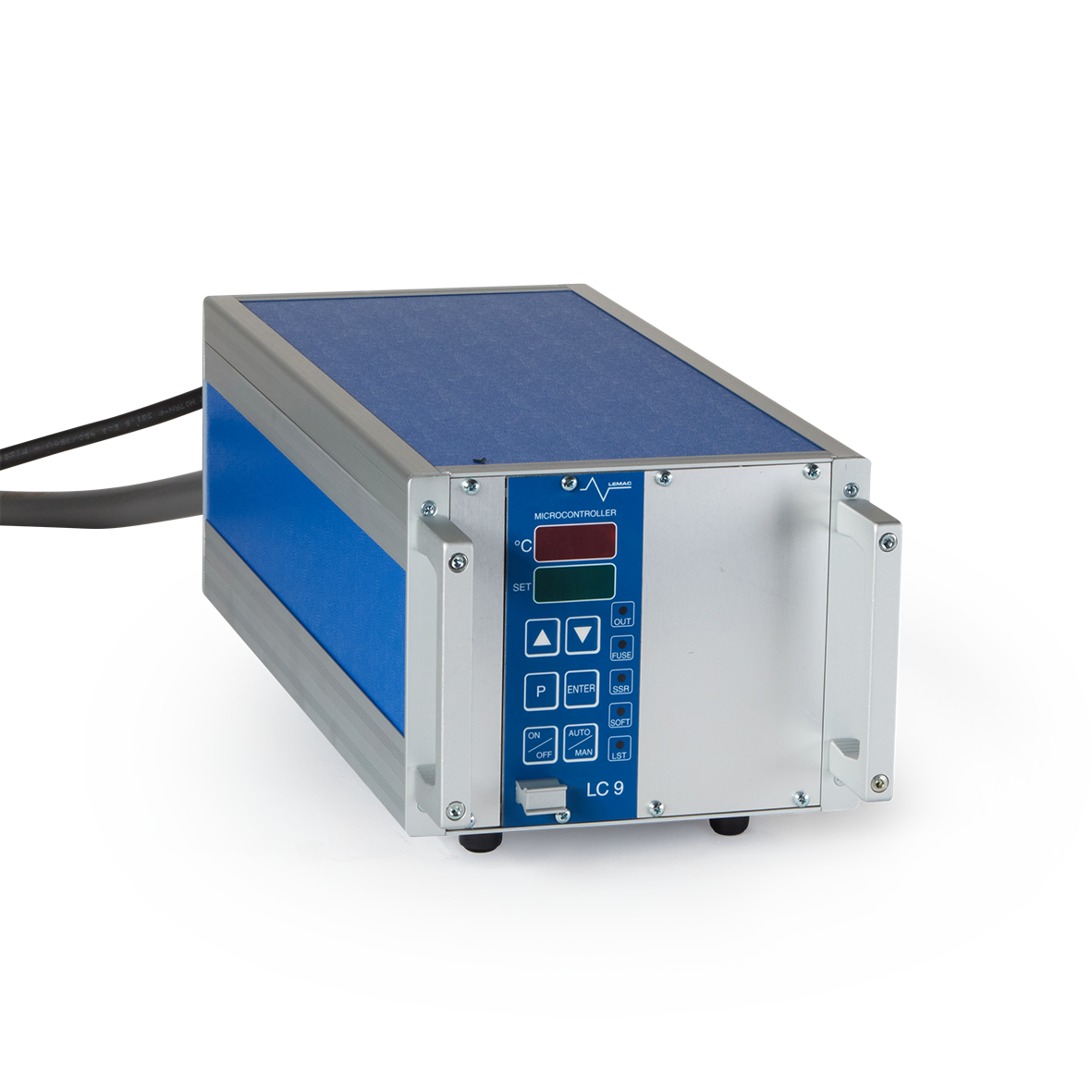

- Display of temperature, parameters and functions via dual 6-digit displays

- Data setting with membrane keyboard

- Control with latest generation PID calculation algorithm

- With auto-reset in case of black-out

- Automatic/manual operation

- Static output with ZERO-CROSSING switching system

- Maximum power 3500W

- Extra-rapid protection fuse 16A

- Max/Min temperature alarm management

- Dynamic set point

- Pre-heating management in duration, temperature and power

- 5 LEDs for signalling operating conditions

- Display of any possible anomalies

- Holding temperature

- Remote set point

- Power circuit opening safety relay

- Load current reading

- Instant power reading

- LST = Lemac Self Tuning

- Self-learning of PID parameters defining the correct operation of the system

- HBD = Signalling of load condition through current reading

- Front pull-out

DESCRIPTION

Equipment features: Control zones 1-96, which can be increased on request - Execution in 9"1/2, 19" and 38" rack cabinets, also trolley-mounted and with transparent PVC protective door - Creation of rack drawers with control and power elements for insertion in existing structures - Possibility of creating multi-voltage equipment - Powers up to 8KW per zone - Power supply 230V single-phase, 230V three-phase, 400V three-phase + neuro frequency 50..60Hz - Magneto-thermal main power switch - Forced ventilation - Power supply cables and multipole connectors for connecting resistors and thermocouples - Socket for external alarm connection

OPTIONS

Visual and/or audible alarm - Connection of external alarms for maintenance temperature management - Programmable device switch-on.